In today’s supply chains, success depends not only on the efficiency of operations but also on the quality of the data behind every decision. Supply chain visibility—the ability to access accurate, real-time information about goods, inventory, and processes—is the foundation for reliable performance measurement. Without it, many critical Key Performance Indicators (KPIs) cannot be accurately monitored, leaving companies vulnerable to operational blind spots and strategic missteps. The benefits of supply chain visibility include improved productivity, enhanced customer satisfaction, and increased profitability by providing greater transparency and control over supply chain processes. This is why supply chain visibility is important: it enables organizations to manage the complexities of modern, global supply chains, respond quickly to disruptions, and maintain competitiveness.

Below are the most important KPIs that are nearly impossible to track without strong supply chain visibility—and why they matter so much for business performance. Understanding why supply chain visibility is crucial helps business leaders prioritize transparency initiatives, as their strategic decisions and company reputation depend on leveraging these practices for long-term success.

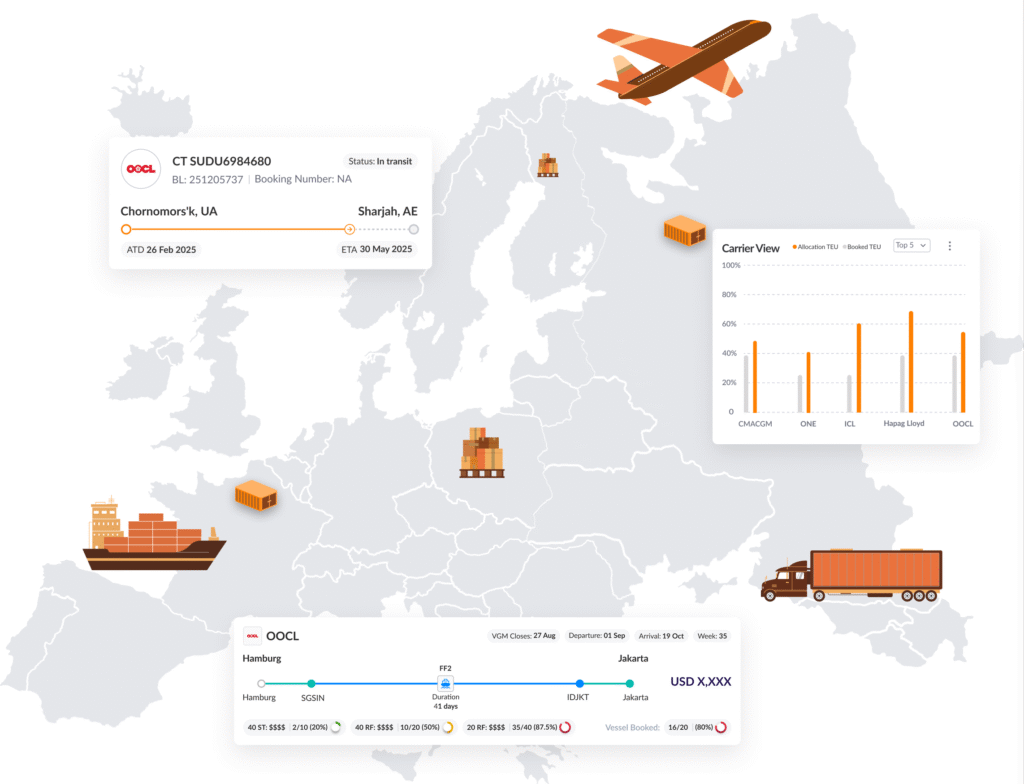

Discover how full visibility of supply chain can transform your operations:

Introduction: Why Visibility is the Foundation of Modern Supply Chains

In today’s fast-paced business landscape, supply chain visibility is a fundamental requirement, an expectation shared by both customers and partners. As supply chains grow increasingly complex and global, the ability to monitor and manage supply chain operations in real-time has become the backbone of successful organizations. Achieving full visibility across the entire supply chain network empowers companies to make informed decisions, quickly respond to disruptions, and adapt to changing customer demands. This level of chain visibility not only helps reduce costs but also drives higher customer satisfaction by ensuring products reach their destination on time and in optimal condition. Ultimately, supply chain visibility is the foundation that supports agile, resilient, and high-performing supply chains.

1. On-Time Delivery Rate (OTD)

On-time delivery is one of the most critical metrics for customer satisfaction. Without full visibility across the supply chain, tracking shipment status and identifying the root causes of delays is challenging. Real-time insights into production progress, transportation status, and customs clearance enable companies to detect potential delays early and take corrective action. Enhanced visibility also allows companies to monitor products all the way to the customer’s doorstep, ensuring timely and accurate deliveries.

2. Perfect Order Rate

The Perfect Order Rate measures the percentage of orders delivered complete, error-free, on time, and undamaged. Effective data collection is necessary to monitor each stage of the order process. Tracking this KPI requires data from multiple touchpoints—inventory, picking, packing, and transportation. Data integration from different systems is essential to ensure accurate perfect order tracking. Without supply chain visibility, inaccuracies such as incorrect stock levels, damaged goods, or wrong shipments may go unnoticed for too long.

3. Inventory Management and Turnover

Inventory turnover shows how efficiently stock is being used. Inadequate visibility can lead to inventory shortages and inventory shortfalls, which disrupt product flow and hinder order fulfillment. Companies with poor visibility risk overstocking, stockouts, or carrying obsolete items because they lack accurate real-time inventory data. Real-time visibility helps companies quickly identify and address inventory shortages and shortfalls to maintain optimal turnover rates. Supply chain visibility enables better demand forecasting and reduces capital tied up in warehouses.

4. Lead Time

Lead time—the duration from order placement to delivery—is a key indicator of supply chain responsiveness. Tracking supply chain activities, such as monitoring quotes, order receipts, and proof of delivery, is essential for understanding and improving lead time. Without visibility, delays remain hidden until it’s too late to act. A transparent supply chain helps pinpoint bottlenecks in procurement, production, or transport so they can be addressed proactively. Mapping and optimizing supply chain processes can significantly reduce lead time.

5. Transportation Cost per Unit

Visibility allows companies to accurately allocate transportation costs—by product, order, or customer. Supply chain visibility leads to cost savings by identifying inefficiencies in transportation processes. Without a complete cost breakdown across the entire journey, optimization opportunities are easily missed. Supply chain visibility highlights inefficient routes, low load utilization, and costly express shipments. Data sharing among stakeholders enables better transportation cost management and optimization.

6. Return Rate

The return rate is not just an e-commerce metric—it affects every industry. Reliance on manual processes can make it difficult to trace and resolve return issues efficiently. Without transparency, it’s difficult to determine whether returns are caused by damage, incorrect items, or inadequate packaging. Supply chain visibility makes it possible to trace the problem back to its source and prevent future issues.

7. Demurrage & Detention Costs

Demurrage and detention costs are expenses that often fly under the radar, since many companies don’t budget for them or even fully track these charges. Without clear visibility, it’s hard to know how much is spent annually or when these costs occur.

Using Logward’s Freight Rate Management and Transport Monitoring capabilities, companies gain transparency on when and how much these costs will be, based on their individual agreements with shipping lines.

Better visibility enables smarter decisions—for example, a company might decide it’s cheaper to pay demurrage fees and leave a container at the port for a few extra days, rather than rushing to unload and pay for expensive overtime labor in their warehouse. Alternatively, if the demurrage fees are high, they might run an extra shift or arrange faster transport to avoid these charges altogether.

Why Supply Chain Visibility Is a Game-Changer

Without end-to-end visibility, KPI tracking becomes guesswork. Data often resides in disconnected systems, is outdated, or contradicts other sources. With supply chain visibility, information flows seamlessly from supplier order to final delivery, enabling:

- Proactive actions instead of reactive fixes

- Better forecasting thanks to consistent, real-time data

- Faster problem resolution when issues arise

- More sustainable decisions supported by complete process insights

Conclusion

If you want to measure your supply chain KPIs accurately, supply chain visibility is non-negotiable. It’s the foundation for correct KPI tracking, timely identification of bottlenecks, and targeted performance improvements. Supply chain visibility also helps companies anticipate and manage supply chain disruptions, ensuring greater resilience in the face of global events and economic challenges. Businesses that invest in visibility gain a competitive edge while building the framework for long-term efficiency and customer satisfaction. Investing in supply chain visibility software further supports accurate KPI tracking and operational excellence by providing real-time insights, enhanced data security, and integration across complex logistics networks.